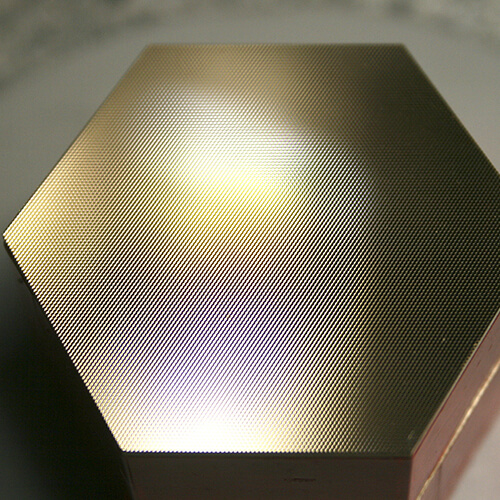

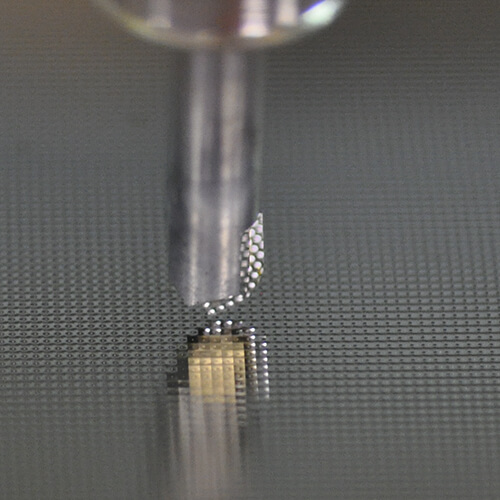

LT Ultra offers the appropriate manufacturing technology for the production of embossing tools with optical surface qualities through the machining of metal surfaces, allowing economical replication in high quantities. Examples of microstructuring include the production of microfluidics or microlenses on our ultra-precision multi-axis machines. We can directly manufacture the structures in various materials, such as brass, electroless nickel, or selected hardened steels.

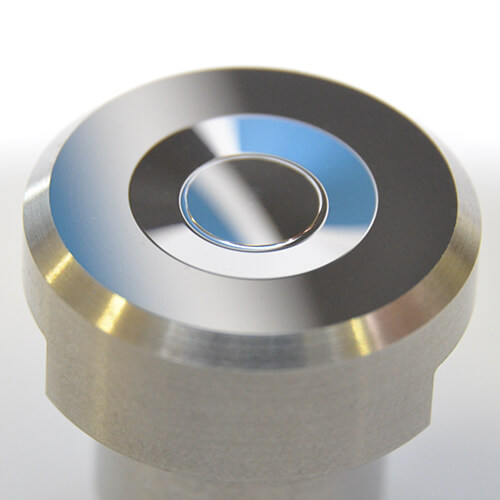

For the replicative production of optical components, ultra-precision mold inserts made of steel are particularly interesting due to their very high service life compared to other materials. To avoid final polishing, which often leads to undesirable shape changes or is impossible due to high structural density, LT Ultra offers ultrasonic-assisted machining of steels with geometrically defined cutting edges made of monocrystalline diamond. This technology allows optical quality to be achieved on low-carbon steels. The blanks are pre-turned with CBN tools and then ultrasonically finished with diamond tools on the same machine without having to unclamp or reclamp the workpiece. In series production, we achieve arithmetic surface roughness of Ra(Sa) < 3 nm.

LT Ultra can provide complete delivery of the embossing insert or the machining of supplied parts. Our experience from many years of manufacturing series and small series ensures your quality and precision.

The achievable accuracies and surface roughness depend on:

- The substrate dimensions

- The specified optical contour

- The materials used

- Electroless Nickel (High Phosphorus Content 10 – 14%)

- Brass

- Plastic Mold Steel

Contact persons

| Georg Boscher | +49 (0) 7552 – 4 05 99-42 |

| Tobias Sieber | +49 (0) 7552 – 4 05 99-83 |

| Responsible for: | Sales metal optics and tools |