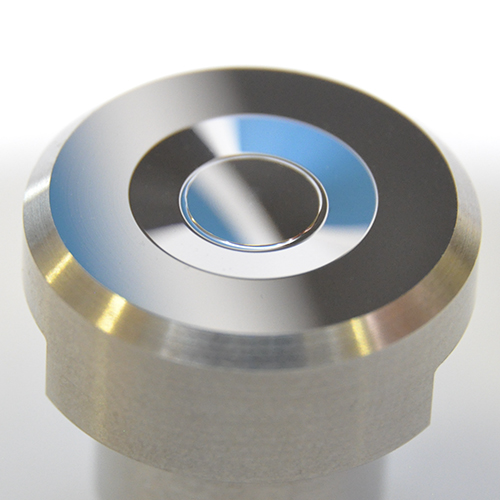

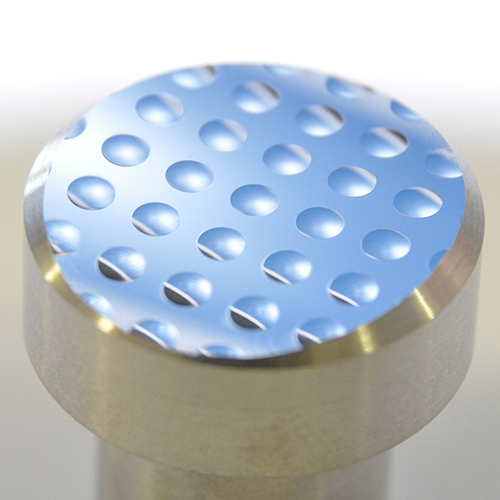

LT Ultra is your partner for producing optical surface qualities in injection molding inserts. For example, we can manufacture inserts for the injection molding of multifocal lenses, as well as mold inserts for microlenses or components for vehicle lighting systems. In addition to simple geometries such as spheres or aspheres, we primarily produce non-rotationally symmetric components and freeform surfaces.

Mold inserts for high service life can be realized in electroless nickel (NiP). Here, machining can be done directly in the nickel. The advantage is that the very durable nickel can also be deposited on substrates that would otherwise be difficult or costly to bring to optical quality. LT Ultra offers complete delivery of the mold insert as well as the machining of supplied parts upon request.

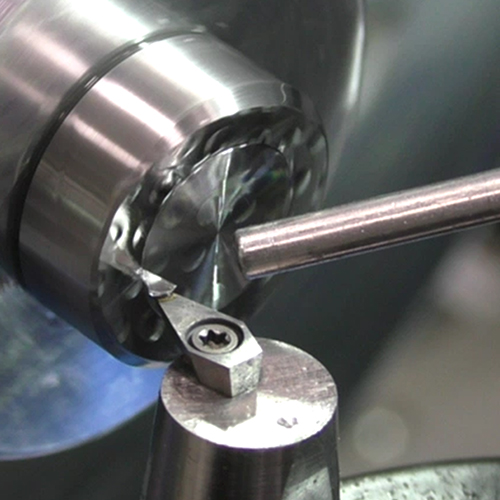

When particularly high service life is expected from ultra-precision mold inserts, steel can be the best material choice. Previously, final polishing of steel inserts often led to undesirable shape changes or was not possible due to high structural density. LT Ultra offers ultrasonic-assisted machining of steels with geometrically defined cutting edges made of monocrystalline diamond. This technology allows optical qualities to be achieved on hardened, low-carbon steels. The workpieces can be pre-turned with CBN tools and then ultrasonically finished with diamond tools on the same machine in a single clamping. In series production, we achieve arithmetic surface roughness of Ra(Sa) < 3 nm. Our experience from many years of manufacturing series and small series ensures your quality and precision.